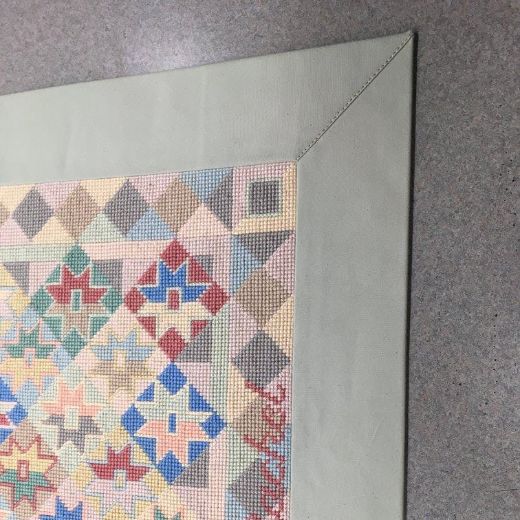

For many years, Ray-Burt’s provided pre-fabrication cutting and edging services for carpet layers but, via unsolicited demand, we’ve evolved into one of the premier producers of high quality custom area rugs in the Northwest. Our expertise in the construction, repair and cleaning of rugs and carpeting provides an edge other fabricators may not have.

We see, on a daily basis, how natural and synthetic materials lay, wear and respond to cleaning. We know when gluing is appropriate and when hand stitching is a necessity to secure seams. We consider nap lay, fabric bias & stretch when cleaning, repairing or piecing. We understand how foot traffic, furniture placement and underlayment play into long term appearance and wear.

In addition to understanding long-term materials and performance issues, we’ve spent years honing our skills at fitting carpet and rugs into custom environments such as yachts, motor coaches and multi-directional staircases. We take great pride in the success of our template and measuring processes, as well as our awareness of fabric consumption.

One of the reasons fabrication has become such a large part of our business is because, over time, we’ve witnessed the disappointment of designers and/or end users that have come to us after having rugs poorly produced elsewhere. Because of our outstanding reputation within the industry, they’ve brought these projects to us hoping we could correct problems. At times, we have been able to improve their situation. However, we believe there’s no substitute for constructing something right the first time. Exercising our commitment to this mindset, we began fabricating rugs ourselves. Our quality became evident and we now produce custom rugs for installations worldwide. We combine skill, true craftsmanship and experience to build the most reliable, suitable product possible for your installation. We’re as comfortable conversing with designers as we are with end users and always respect the boundaries of customer contact.